What Are the Different Types of Natural Gas Pipelines?

Natural gas pipelines come in three main types that you'll encounter in the energy transportation system. Gathering lines collect raw gas from wells at lower pressures, transmission lines serve as the high-pressure backbone network for long-distance transport, and distribution lines deliver gas at reduced pressures to end users.

Each type has unique safety standards and construction requirements based on its classification. Understanding these distinctions helps reveal how the entire gas delivery system functions together.

Understanding Pipeline Classification Systems

Natural gas pipelines form a complex network that's organized into distinct classifications based on their function and operational characteristics. You'll find gathering lines operating at lower pressures, collecting raw gas from wells and moving it to processing facilities. These connect to transmission lines, which are the backbone of the pipeline network, carrying large gas volumes across vast distances at high pressures. When the gas needs to reach your home or business, distribution pipelines take over.

They're smaller in diameter and operate at reduced pressures compared to transmission lines. Local utility companies manage these final delivery systems. Understanding these classifications is essential because each type serves a specific purpose, with different pressure requirements, construction materials, and safety standards. Together, they create an integrated system that safely moves natural gas from production to consumption. Similar to direct current flow, gas in these pipelines moves consistently in one direction from source to destination.

Major Components of Natural Gas Pipeline Networks

Building on these pipeline classifications, let's examine the physical components that make up gas pipeline networks.

You'll find a gathering system at the start, where smaller pipelines collect raw gas from wells and direct it to processing facilities. These operate at lower pressures to safely transport the initial product. From there, transmission pipelines take over, moving massive volumes of gas across long distances. These large-diameter pipes handle pressures up to 1,500 psi to maintain ideal flow rates.

Distribution lines form the final delivery network, operating at much lower pressures between 0.25 to 200 psi to safely bring gas to your home or business. Throughout this system, you'll also encounter flowlines connecting production stages and feeder pipelines that link different network sections, ensuring consistent gas delivery across the entire infrastructure. Safety inspectors often use green flashlights during night checks because they preserve night vision while providing excellent contrast for examining pipeline components.

Regional and International Pipeline Networks

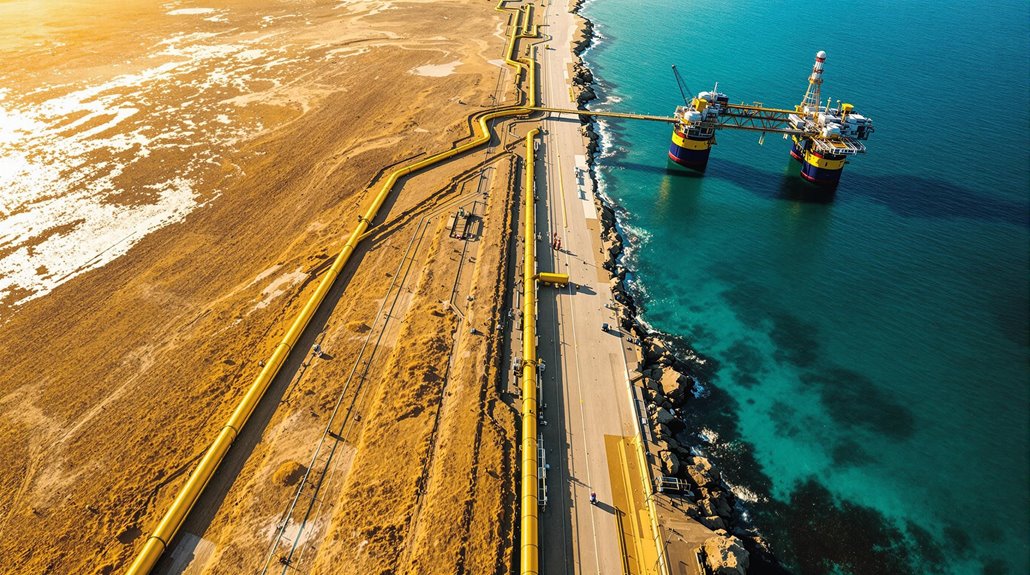

How do gas pipelines connect our world? You'll find extensive pipeline networks operating at both regional and international scales to move natural gas where it's needed most. Transcontinental pipelines like the Altai and West African Gas Pipeline transport gas over long distances, crossing multiple countries to link major production and consumption hubs.

Within specific geographic regions, networks such as the Arab Gas Pipeline and Maghreb-Europe Gas Pipeline efficiently connect nearby countries and markets. For international trade across oceans, LNG terminals like Kenai in Alaska and Cove Point in Maryland enable global gas distribution through liquefaction and shipping. Meanwhile, offshore pipelines connect sea-based production platforms to land-based facilities.

Some specialized systems, like Hinshaw pipelines, operate under state regulation despite crossing borders, adding flexibility to regional distribution networks. Modern pipeline monitoring systems can utilize night vision technology to detect leaks and maintain security across vast networks in low-light conditions.

Materials and Construction Methods

The choice of materials and construction techniques plays a central role in pipeline reliability and longevity. Steel pipelines remain the industry standard for natural gas transportation due to their high tensile strength and ability to handle large diameters. While cast iron was historically common, it's now primarily used in older infrastructure for water and sewage systems. When it comes to pipeline construction, you'll find two main installation methods. Transmission lines typically use open trenches, which are more suitable for long-distance installations.

However, for distribution pipelines in urban areas, you'll more likely encounter trenchless installation methods to avoid damaging existing utilities. While plastic pipelines offer good chemical resistance, they're less common in natural gas transmission due to their lower tensile strength compared to steel, which continues to dominate large-scale gas transportation infrastructure. Like LED emergency lights, modern pipeline systems prioritize efficiency and durability to ensure reliable long-term performance.

Safety Standards and Regulatory Requirements

Since natural gas pipelines transport highly flammable materials, stringent safety standards and regulatory oversight are critical for public safety. You'll find that pipeline operators must comply with federal regulations that mandate regular inspections, maintenance schedules, and emergency response protocols.

Throughout the transmission system, you'll notice sophisticated pressure monitoring devices and automated shutoff valves that help control the flow of gas and prevent accidents. These safety standards require operators to maintain minimum distances from buildings, conduct periodic leak detection surveys, and implement corrosion prevention measures.

You must also be aware that operators need to provide exhaustive training for their personnel, maintain detailed maintenance records, and develop emergency response plans. Regular audits and inspections by regulatory agencies guarantee compliance with these essential safety requirements.

Pipeline Pressure Management Systems

Managing pressure effectively across natural gas pipeline networks requires sophisticated control systems and monitoring equipment. You'll find pressure relief valves and regulators strategically placed throughout the system to maintain safe operating conditions. When natural gas travels long distances through transmission pipelines, compressor stations augment the pressure to keep the gas flowing efficiently.

SCADA systems let operators monitor and control pipeline pressure remotely, ensuring ideal performance across the network. Before gas enters local distribution systems, pressure reducing stations lower the transmission line pressure to safer levels. For added protection, you'll see automatic slam-shut valves that immediately stop gas flow if pressure exceeds safe limits. These integrated pressure management components work together to deliver natural gas safely and reliably from source to end-user.

Onshore Vs Offshore Pipeline Infrastructure

While both serve essential roles in natural gas transportation, onshore and offshore pipeline infrastructures differ considerably in their design and operational requirements. When you compare gas pipelines in these environments, you'll find that offshore pipelines typically have smaller diameters and operate at higher pressures than their onshore counterparts. They must withstand unique challenges like water pressure and marine corrosion.

You'll notice that offshore pipelines require specialized construction methods, including pipe-laying ships and underwater drilling techniques. Maintaining these subsea systems is more complex, often requiring ROVs for inspection. In contrast, onshore pipelines focus primarily on gathering, transmission, and distribution within land-based facilities. While they face their own environmental challenges, they're generally more accessible for maintenance and repairs than their underwater counterparts.

Gas Transportation and Storage Solutions

The natural gas pipeline network functions as an intricate web of specialized conduits, each serving distinct transportation needs. You'll find gathering pipelines collecting raw gas from wells and moving it to processing facilities at lower pressures. These connect to transmission lines that carry huge volumes across vast distances under high pressure.

When gas needs to reach your home or business, distribution pipelines take over, operating at reduced pressures for safe delivery to end users. Throughout this excursion, flowlines help transport gas between different production stages, while feeder pipelines guarantee smooth connections across the network's components. This integrated system creates an efficient flow from source to consumer, with each pipeline type optimized for its specific role in moving gas safely and effectively through the transportation chain.

Pipeline Monitoring and Maintenance

Modern pipeline networks rely on sophisticated monitoring systems to safeguard safe, reliable gas transportation. Pipeline monitoring includes continuous remote sensing and data analysis to detect issues like leaks, corrosion, and potential damage from third parties. You'll find automated shut-off valves and pressure monitoring systems that guarantee proper flow and enable quick responses to emergencies.

Pipelines are used in conjunction with regular aerial and ground-based inspections to maintain integrity and identify necessary repairs. To protect these crucial storage and transportation systems, operators employ specialized tools called "smart pigs" that travel inside the pipelines to detect internal and external defects. They also implement preventative maintenance strategies, including cleaning, protective coatings, and cathodic protection systems to fight corrosion and extend the infrastructure's operational life.

Environmental Impact Assessment and Mitigation

Before constructing natural gas pipelines, thorough environmental impact assessments evaluate potential effects on ecosystems, water resources, and local communities. You'll find that these assessments help identify sensitive areas and develop strategies to minimize ecological disruption during construction and operation.

When pipelines used for energy supply cross wetlands or wildlife habitats, you'll need to implement specific mitigation measures. These include horizontal directional drilling to avoid surface disturbance, wildlife crossings to maintain animal migration paths, and restoration of vegetation after construction. You'll also have to monitor air and water quality around the gas pipeline infrastructure to guarantee compliance with environmental regulations.

To protect local communities, you must develop noise reduction strategies, implement dust control measures, and establish emergency response plans for potential leaks or accidents.