How Do Power Transformers Work?

Power transformers work by converting electrical energy between voltage levels through electromagnetic induction. When you send alternating current through the primary winding, it creates a magnetic field in the steel core, which then induces voltage in the secondary winding. The ratio of windings determines whether voltage increases (step-up) or decreases (step-down). Modern transformers achieve 97-99% efficiency using advanced cooling systems and materials. Uncover how these essential components come together to power your world.

The Basic Principles of Electromagnetic Induction

When an electrical current flows through a wire, it creates a magnetic field around that conductor. This principle of electromagnetic induction is essential to how transformers work. You'll find that when you change a magnetic field near a conductor, it induces voltage in that conductor.

In a transformer, you have two sets of wire coils: the primary winding and secondary winding. These coils are wrapped around a magnetic core, typically made of iron or steel. When you apply alternating current to the primary winding, it creates a changing magnetic field. This magnetic flux passes through the core and alters voltage in the secondary winding. The ratio between the number of turns in the primary and secondary windings determines whether the transformer steps voltage up or down, while the electrical current changes inversely to maintain power balance.

Transformers are specifically designed to work with alternating current because its periodic reversal of charge flow is necessary for continuous electromagnetic induction.

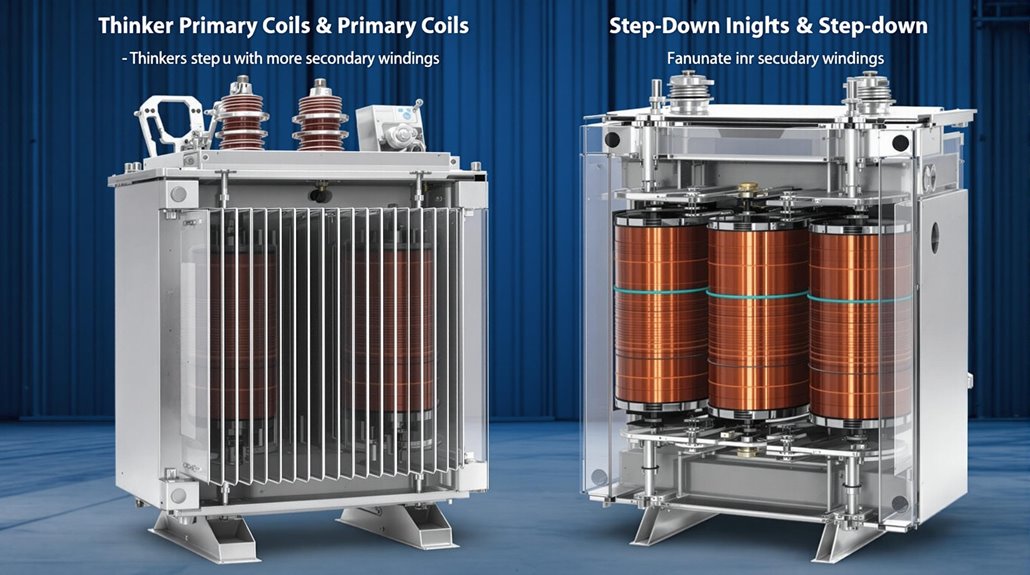

Essential Components of a Power Transformer

Building on the electromagnetic principles we've covered, a power transformer consists of several key parts working together to achieve voltage alteration. The core components include the steel core, primary and secondary windings, insulating materials, and the cooling system.

You'll find the steel core at the transformer's heart, which concentrates and directs electromagnetic flux between windings. The primary windings receive incoming electrical energy, while the secondary windings deliver the modified voltage to your electrical system. Both sets of windings are made of copper or aluminum wire, carefully insulated to prevent short circuits.

Every transformer design includes a cooling mechanism - typically oil or air - to manage heat generated during operation. The tank housing protects these internal components and supports the transformer's overall functionality in power distribution networks. The transformer's ability to efficiently convert AC power makes it fundamental to modern electrical distribution systems.

Step-Up Vs Step-Down Transformers Explained

Power transformers come in two fundamental varieties that serve opposite but equally vital purposes in electrical distribution. Step-up transformers increase voltage from the power source by using more turns in the secondary winding compared to the primary winding. You'll find these at generating stations, where they elevate voltage for efficient transmission across long-distance power lines throughout the power grid.

Step-down transformers do the opposite - they decrease voltage by having fewer secondary turns than primary turns. When electrical power needs to reach your home safely, these transformers reduce the high transmission voltages to usable levels. Both types maintain electrical isolation between their windings through magnetic coupling, ensuring safe power delivery. The ratio of turns between primary and secondary windings directly determines how much the voltage changes, making transformer selection essential for specific applications. Modern transformers increasingly incorporate IoT integration for remote monitoring and real-time diagnostics of their operational status.

The Role of Core Materials and Windings

At the heart of every converter lies a carefully engineered combination of core materials and windings that work together to enable efficient power transfer. When you're dealing with high voltage electricity from power lines, the core's soft iron or silicon steel composition provides an essential path for magnetic flux, making the electrical transformer more efficient.

The principle of electromagnetic induction drives the process where your primary winding creates a magnetic field, which then induces voltage in the secondary coil. You'll find this setup in transformers used in homes and industrial settings. The number of turns in each winding determines whether electrical power is stepped up to high voltages or stepped down for everyday use. The core's material quality and winding design directly impact how effectively the transformer can handle power demands while maintaining ideal performance.

Most residential transformers convert power to alternating current to efficiently distribute electricity over long distances while minimizing energy loss.

Power Loss and Efficiency in Transformers

While converters are remarkably efficient devices, they still experience some power losses during operation. When transformers transfer electric current between two circuits to increase or decrease voltage for long distances between power plants and homes, they typically maintain high efficiency rates of 97-99%.

The main types of power losses you'll encounter in transformers include:

- Core losses from hysteresis in the steel core

- Eddy current losses in the magnetic materials

- Copper losses in the windings

- Heat generation requiring proper cooling

- Air gap losses in the core assembly

These losses are directly proportional to the transformer's load and operating conditions. Modern transformers incorporate advanced materials and cooling systems to maximize safety and effectiveness, ensuring minimal energy waste during power transmission. Regular monitoring and maintenance help maintain ideal performance throughout the transformer's service life.

Cooling Systems and Temperature Management

Since converter components generate significant heat during operation, effective cooling systems are essential for guaranteeing safe operating temperatures. You'll find two principle types of cooling systems used in transformers: oil-based and air-based systems. Oil cooling serves a dual purpose, acting as both an electrical insulator and a heat transfer medium for the windings and core. The oil's temperature changes as it circulates through radiators or heat exchangers.

For smaller transformers, you'll often see forced-air cooling systems where fans direct air across the turns and windings. Larger units may combine multiple cooling methods, including oil circulation with external radiators or water-cooling systems. Automatic temperature monitoring verifies the cooling system responds quickly to prevent overheating, helping maintain optimal performance and prolong the transformer's lifespan.

Safety Features and Protective Mechanisms

Modern power transformers incorporate multiple layers of safety features that work alongside their cooling systems to prevent accidents and equipment damage. You'll find several critical protective mechanisms that safeguard both the equipment and personnel:

- Pressure relief devices and oil level indicators continuously monitor the transformer's internal conditions

- Temperature monitoring systems work with insulating oil to preclude dangerous overheating

- Fuses, circuit breakers, and lightning arrestors protect against electrical surges and short circuits

- Grounding systems effectively dissipate fault currents to avert electric shocks

- Regular dissolved gas analysis helps detect potential issues before they become critical

These safety features work together to guarantee reliable operation while protecting against common transformer failures. When properly maintained, these protective systems drastically reduce the risk of equipment damage and workplace accidents, making modern transformers remarkably safe and dependable.